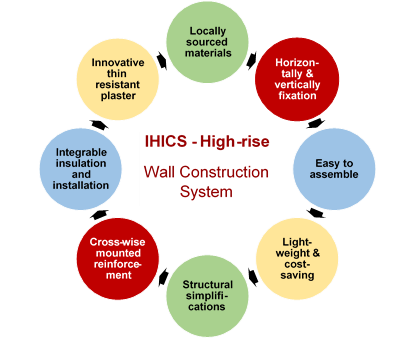

IHICS - HIGH-RISE KEY FEATURES

Unique recipes from IHICS Philippines Corporation are used to manufacture the hollow blocks as well as mortar and plaster. The material mixtures basically consists of limestone, rice husks and cement, which are sourced mostly locally.

IHICS - High-rise wall blocks can be neatly arranged on top of and next to each other.

The fixation of the individual blocks is done horizontally when the cam on one side interlock with the groove on the other. The remaining cavities between the interlocking blocks with the reinforcements running inside are simply filled with IHICS paving joint mortar. The vertical brick laying is also carried out with the special IHICS mortar. This then connects the upper block groove with the block holes on the underside and forms the vertical mechanical fixation.

The blocks are significantly lighter with the same or even improved quality and stability. This makes handling simpler and timesaving. The weight reduction achieved for the walls in turn has a positive effect on the necessary foundation strength of a high-rise construction, and thus directly and indirectly on the overall costs of the construction.

The main advantages of the IHICS - High-rise are the structural simplifications associated with the special shape of the wall blocks. The blocks are simply latched into the vertical reinforcement.

This vertical reinforcement is welded to the floor and ceiling structure before the walls are bricked. What first of all significantly increases the safety of the workers at great heights. And secondly improves the stability of the walls and thus of the entire building structure. Nontheless because the horizontal reinforcement is added to the canal blocks and welded to the skeletal posts similarly.

Additional insulation against heat, cold or noise can easily be achieved by using the bricks with the cavities at the top when building the walls and filling them with insulation, favorably with inexpensive rice shells.

Most electrical and plumbing installations can directly be laid into resp. pulled into the blocks. This eliminates the need for time-consuming work to create the appropriate recesses.

The innovative IHICS plaster adheres better and does not form the frequently observed hairline cracks when drying out. The plaster is thanks to its mixture recipe simpler and easier to apply as well as more resistant, despite its thin application of only approx. 5mm. This has at the end also an additional positive effect on the total weight of the building.